Those

Magnificent Men and their Atomic Machines

Burning

Metal: The Los Alamos Molten Plutonium Reactor Experiment and the

History of the Fast Breeder

Part

I

With special

thanks to Prof. R. M. Kiehn

Note on

Notation

Money is going to

be talked about a lot, but the value of the dollar has been different

from year to year. In each case, unless otherwise specified, values

will be given in the amount for the year in question, followed in

parentheses by the equivalent value in 2011 dollars.

In

the Beginning

When the Atomic

Energy Commission (AEC) was formed in 1947, it inherited from the

Manhattan

Project a sprawling empire of factories, test sites,

laboratories, and development programs, organized around one purpose:

the design and manufacturing of nuclear weapons. And for the first

decade of its existence, that was the AEC's primary purpose as well.

But the hopes of most of the scientists and engineers, and the

citizens who paid their salaries, were not of weapons – they were

of reactors, nuclear reactors to provide cheap, clean, abundant

energy, energy to propel

ships and planes,

energy to free man from his age-old burden of labor, energy to bring

permanent prosperity to the world.

In 1954, the AEC began to turn those hopes into reality. Although power reactor research had started at a low level before the AEC had even been formed, the requirements of national defense had limited most work to military applications such as naval propulsion. President Eisenhower's “Atoms for Peace” speech in December of 1953, along with growing pressure from the powerful Joint Committee on Atomic Energy, led to a steady expansion in the AEC's funding for civilian power reactor research. Developing a power reactor would be an immensely difficult, expensive, and time-consuming task. The AEC was well-armed for the challenge, with unprecedented public funding and the lion's share of the nation's talent in nuclear science and engineering. But what would a power reactor actually look like?

The reactors at Hanford, built during the war to make plutonium for bombs, were adequate for their task, but clearly unsuited to generating electrical power. And no one really knew what a power reactor would look like – after all, none had been built before.

At the most basic

level, any nuclear reactor produces power through a fission reaction:

neutrons split atoms of uranium-235 or plutonium, producing more

neutrons, causing more fissions, and so on, in a chain reaction. So

long as the reaction produces as many neutrons as are needed and no

more, the reactor is said to be critical. Heat produced by the

fission is then removed by a coolant and used to drive a turbine,

producing electricity.

In most (but not all) reactors, a moderater is also present in the core – a material made of light elements such as hydrogen or carbon. Neutrons bounce off the moderator, leaving some of their energy behind and slowing down as they go; counterintuitively, slower neutrons are more likely to cause fission than fast neutrons, so moderated reactors are easier to design and build than unmoderated, or “fast”, reactors.

But, while the broad outline was clear, many aspects were unspecified. Would the reactor use plutonium or uranium for fuel, at what enrichment level, and in what chemical form? Would it use a moderator and, if so, which one? What coolant would it use? What temperature would it operate it? Dozens of different proposals were circulating, and each had its advocates.

Light

Water Reactors (LWRs), using pressurized water as coolant and

moderator and enriched uranium solid fuel, had the virtue of relative

simplicity and were compact enough to use for naval propulsion.

Heavy

water reactors could be fueled with unenriched uranium, although

the large amounts of heavy water needed add considerably to capital

costs. Organic-moderated

reactors can run at atmospheric pressure, without an expensive

pressure vessel, but the hydrocarbon moderator tends to decompose in

the intense radiation. Sodium-cooled

reactors can operate at a higher temperature and therefore have

better thermal efficiency, but sodium burns merrily on contact with

air or water. Aqueous

homogenous reactors, molten

salt reactors, gas-cooled

reactors, they all had their supporters, and the AEC turned many

of these ideas into hardware. Between 1953 and 1962, the AEC built

14 civilian power reactor prototypes and collaborated with industrial

partners to build 4 more, using 7 different types of coolant, 6 types

of moderator, and 7 different fuel forms.

Most of these prototypes were small, low power reactors, generating heat but no electricity, but they served to explore the properties of a wide variety of reactor designs. Besides power reactor prototypes, the AEC also built 6 land-bound prototypes for naval propulsion, 5 reactors for air-breathing missile and aircraft propulsion, 3 for satellite power supplies, and 7 transportable reactors for remote military bases, as well as reactors for materials testing, to generate neutrons for research, and for producing radioactive isotopes.

However, although the AEC pursued a vast array of different concepts, two reactor types were clear favorites. The light water reactor took an early lead, thanks in part to the massive investment the AEC poured into Admiral Hyman Rickover's naval propulsion program – from 1950 to 1962 the AEC spent $7.24 billion (2011 dollars) on naval propulsion, almost all of it on light water reactors, compared to $5.41 billion (2011 dollars) on civilian power reactors of all kinds. The LWR offered a way to get some kind of reactor into commercial service soon. That was a critical advantage for many in the AEC. The Soviets and Western Europeans were both building power reactors; the US could not afford to be left behind in the peaceful use of the atom. And although the AEC reactor program enjoyed wide support within Congress – and corresponding budgets – that would not last forever. The longer it took to get reactors out of the labs and onto the market, the greater the program would be at risk from impatient politicians seeing little advantage in a massively expensive project that might pay off in ten or twenty years.

Light water reactors, it was hoped, could make a meaningful contribution to the national economy before 1970. In 1958 the AEC set a goal of making nuclear electricity from LWRs cost-competitive in regions with high fuel costs, where fossil fuels were at a competitive disadvantage, within ten years. It would not be the cheap, plentiful energy promised by the technotopians, at least not at first, but it would be a useful technology and pave the way for better designs later. In the long run, however, it would have to be replaced. There simply wasn't enough uranium.

The availability of uranium was a major constraint on plans for an atomic-powered civilization in the 40s and 50s. When the AEC was first organized, it was unclear if there was even enough uranium for the weapons program, much less civil nuclear power. The supply situation eased as high prices led to discovery of new deposits, but there was still only uranium equal to several decades of global electrical consumption if burnt in light water reactors. And that was assuming stable demand – atomic energy was supposed to industrialize the third world, bring light to the darkness and prosperity to the impoverished, not keep things ticking over as they were.

The preferred solution was the Liquid-Metal-cooled Fast Breeder Reactor (LMFBR). Uranium, as it emerges from the mine, comes in two isotopes: uranium-235 (0.7%) and uranium-238 (99.3%). Only U-235 is fissile – although U-238 can fission if hit by fast neutrons, it releases no new neutrons when it splits, so it cannot support a chain reaction. U-235 releases two or three. If one of those neutrons triggers another U-235 fission, a chain reaction is created, as each fission causes another fission in turn. But only one neutron from each fission is needed to sustain the chain reaction.

The other neutrons might leak out of the core or be absorbed by the reactor structure, or they might be absorbed by an atom of U-238, which then undergoes radioactive decay to become plutonium-239 – which is also fissile. Thorium-232 can be converted into fissile uranium-233 in the same way. In a light water reactor, too many neutrons are lost, so plutonium is produced more slowly than the existing fuel is consumed. Such a reactor is called a “burner” or “converter”. But it is possible to build a reactor where plutonium is produced faster than the existing fuel is consumed – a “breeder”.

Since uranium-235 makes up such a small fraction of uranium ore, burners such as LWRs can only tap about 1% of the ore's energy potential. A breeder can, in theory, use all of it. Like magic, several decades of uranium becomes several millennia. In fact, a breeder could be so fuel-efficient it could cost-effectively tap the faint wisps of uranium dissolved in ordinary granite and seawater – a supply of fuel so vast it is functionally infinite. This would be power to fulfill the technotopian dreams, power to bring prosperity to the world, power forever.

The LMFBR would be that breeder. As envisioned by the AEC, it would consist of a dense core of highly-enriched metallic or ceramic fuel rods of plutonium or U-235, cooled by liquid sodium. The liquid sodium would flow out of the core to a heat exchanger, where its heat would be transferred to a second sodium coolant loop, which would heat water in a steam generator to drive a turbine. The core would be surrounded by a layer of U-238, called a “breeding blanket”, which would be slowly transformed into plutonium by neutrons emerging from the core. Periodically fuel rods would be removed from the blanket and chemically processed to separate the plutonium and remaining uranium, with the uranium returning to the blanket while the plutonium was added to the core.

The LMFBR would be a fast reactor, meaning that it would not use a moderator. While fast reactors are harder to build and control than thermal reactors, they have major advantages as breeders. Plutonium-239 struck by a neutron sometimes absorbs the neutron to become Plutonium-240 instead of fissioning; this happens much more frequently when the neutron is slow than when it is fast, making plutonium breeding impractical in moderated reactors (although they can still breed thorium-232 into uranium-233). Also, although this was not a serious concern yet in the 50s, fast neutrons can fission the transuranic isotopes that form the majority of long-lived nuclear waste, destroying them.

Research into the LMFBR began in the late 40s, with Argonne National Laboratory in charge of the project. The first LMFBR became operational in 1951, when Experimental Breeder Reactor-1 lit a string of light bulbs at the National Reactor Test Station in Idaho. A few years later, chemical analysis of the uranium-238 blanket around the core showed that, indeed, the reactor was producing more fuel than it was consuming. EBR-1 operated until 1964, with a brief interruption to repair the reactor after an accident in 1955. EBR-1's successor, the Experimental Breeder Reactor-2, was approved in 1954, and a consortium of private companies, the Power Reactor Development Company, began building their own prototype in 1957, Enrico Fermi Unit 1.

Figure 1:

Experimental Breeder Reactor-1

The fast breeder

had disadvantages. Molten sodium bursts into flame on contact with

air, and explodes

on contact with water. More worryingly, fast reactors can blow up.

The high speed of the neutrons means the reactor can change power

more quickly than a thermal reactor – faster, potentially, then

control systems can react. In a light water reactor, if the

reaction begins to go out of control and the fuel heats up, the water

moderator will expand and eventually boil. As the density of the

water drops, neutrons passing through the water bounce off fewer

atoms and are slowed down less, making them less likely to cause

fission, in turn reducing the rate of reaction. This is called a

negative temperature

coefficient of reactivity, and it makes light water reactors –

and other reactors with similar properties – relatively easy to

control.

A negative temperature coefficient of reactivity can be engineered into a fast breeder – for example, by exploiting the thermal expansion of metallic fuel rods – but it is significantly harder to achieve. In particular, if the reactor became hot enough for the sodium coolant to boil, the reaction could speed up as fewer neutrons were absorbed, causing the sodium to boil more. An explosion is possible – not the explosion of an atom bomb, not an explosion that could wipe out a city by itself, but possibly one big enough to crack the reactor vessel. Exactly how serious this risk is is still not clear. Clever engineering can reduce or perhaps eliminate the problem, for example by the use of “pancake” designs using very thin cores where, if the sodium began to boil, the increased reactivity from lower absorption would be offset by fewer neutrons being reflected back into the core from above and below. But keeping a fast reactor safe and stable remains a significantly greater challenge than in a light water reactor.

Other possibilities for breeders were circulating besides the LMFBR, such as for gas-cooled fast breeders and for thermal breeders such as the Shippingport light water thorium breeder. But gas is a poor coolant compared to liquid sodium, and the long doubling times of most thermal breeders, combined with the unfamiliarity of the AEC with thorium compared to uranium and plutonium, made the LMFBR an early front runner among the breeders.

The breeder had a special attraction to the scientists of the AEC, even more than conventional power reactors. Although it would not be a major social concern until the 70s, experts had been aware since the 19th century that fossil fuel supplies are finite, and that a replacement would eventually be needed. The breeder seemed to offer that replacement. Scientists such as Oak Ridge's Alvin Weinberg spoke of “the asymptotic state of humanity”, and of developing technologies that could power an affluent lifestyle for billions of people for millennia. People talked about nuclear fission, and breeding in particular, as almost magical – the word “alchemy” was sometimes used.

It was in this context that K division of Los Alamos Scientific Laboratory (LASL), usually known for weapons, proposed a new, unusual type of reactor, which they called the Los Alamos Molten Plutonium Reactor Experiment, or LAMPRE. LAMPRE would be a radically different approach to the fast breeder: fueled by molten plutonium, it would operate at high temperatures, breed efficiently, be easy to control, and push the envelope of materials science almost to the breaking point.

Reactors at

Los Alamos

LAMPRE was not Los Alamos'

first reactor. That honor went to the LOPO,

which went critical even before World War II had ended. LOPO –

which stood for “LOw POwer”, since it produced essentially no

thermal energy – was a 1-foot-diameter stainless steel sphere

containing 14% enriched uranyl sulfate dissolved in water and

surrounded by a beryllia reflector, and used the country's entire

stock of enriched uranium at the time. Also called the Water Boiler

– both for security and because the fuel solution seemed to bubble

as gamma rays split water molecules – LOPO was used to calculate

nuclear constants and do other experiments to support the development

of the atomic bomb. LOPO was eventually succeeded by two more Water

Boilers, HYPO and SUPO, the latter of which remained in regular use

until 1974. Los Alamos also operated Clementine,

a mercury-cooled plutonium-fueled fast reactor, as a source of fast

neutrons for physics experiments.

Figure 2: SUPO Reactor Core

Before Being Covered by Shielding

Clementine and the LOPO series

were primarily research tools. But Los Alamos also branched out

into power reactors. Norris

Bradbury, the laboratory's director, was worried that a lab

focused on weapons would have difficulty attracting scientific

talent, and when the AEC expanded its power reactor research in 1954,

he asked AEC Chairman Lewis

Strauss to allow LASL to join in. Strauss was amenable, and in

the mid 50s LASL developed the Los Alamos Power Reactor Experiment-1

and -2, power reactor prototypes similar to the LOPO series, fueled

by uranium dissolved in phosphoric acid.

One of the scientists working for K division on the LAPRE project was R. M. Kiehn. Kiehn joined Los Alamos fresh out of graduate school at MIT, where he had studied ideas for fast reactors and become fascinated with the idea of breeders. A fast breeder would necessarily use plutonium, and Los Alamos was one of the very few places in the world that had access to plutonium. So, turning down several more lucrative job offers, Kiehn went to Los Alamos in 1953.

In the 50s, Los Alamos expected its scientists to spend half their time working on “programmatic” work – that is, work aimed at weapons or other national security requirements. But, so long as you completed your programmatic assignments, you were mostly free to spend the remaining time on projects of your own choosing. Kiehn, becoming bored with aqueous reactors like the LAPRE, wanted to work on fast breeders. At the same time, Los Alamos's Art Coffinberry had been working on ways to confine intensely corrosive molten plutonium in tantalum, as part of an effort to find more efficient means of extracting plutonium from spent fuel.

If a fast reactor could be built with a molten core, Kiehn reasoned, it would be much, much easier to control. If the reactor began to overheat, the liquid fuel itself would expand, allowing more neutrons to leak out and slowing the reaction down. The reactor would be self-stabilizing, like a light water reactor. Existing fluid fuel reactors like the LOPO and LAPRE series showed that the approach might work, but those reactors used dilute solutions of uranium sulfate in water. Kiehn's proposed core would use molten plutonium, alloyed with small amounts of another metal to reduce its melting point.

Los Alamos was not the only group pursuing fluid fuel breeders, but it was the only group trying to build a fluid-fueled fast breeder. With the exception of the Oak Ridge MSR project and Brookhaven's liquid metal fueled thermal breeder, the AEC's fluid fuel reactors all used water-based fuel, which had to be held under high pressure if it was to be used at temperatures suitable for a power reactor. The molten plutonium fuel and sodium coolant of the LAMPRE would be at or near room pressure.

However, there were serious obstacles to overcome before LAMPRE could become a useful reactor. Fission product gases might not disengage from the fuel properly; bubbles of fission gas in the fuel might cause power fluctuations. Or they might bubble on the reactor vessel walls and block the flow of heat from the fuel into the coolant. Solid fission products might deposit on the surfaces.

And molten plutonium is intensely corrosive. There are very few materials that can withstand plutonium and sodium corrosion, high temperatures, and intense radiation. Transition metals, including conventional construction materials such as stainless steel, form low-melting-point alloys with plutonium, which would quickly eat through them. Of the refractory metals, tungsten and molybdenum could not be easily fabricated at the time, while chromium, vanadium, and titanium failed to stand up to molten plutonium in lab tests.

That left tantalum and niobium, with tantalum gaining the edge. Tantalum is a dark, blue-gray metal known primarily for its resistance to corrosion, used in high-performance alloys for jet engines and metalworking equipment. It has good thermal properties, good structural strength at high temperature, can be welded, has somewhat better corrosion resistance than niobium, and was already being experimented with at Los Alamos for plutonium containment. It does tend to absorb neutrons, but not to an intolerable degree in the fast neutron spectrum. And extensive testing – over 9,000 hours of static testing and two weeks of dynamic testing – showed that it has adequate resistance to corrosion by liquid sodium, the planned coolant.

No one had ever used tantalum, or any other material, under conditions remotely comparable to what was planned. But the prospect of a safe, controllable, cost-effective breeder was worth pursuing – and, in the 50s, that meant building one. The project was allocated $1.5 million ($11.8 million) in 1957 to start work.

Designing the Reactor

The initial nuclear design of

LAMPRE-1 was finished around 1957, and a patent application filed for

the concept. The original plan was that LAMPRE-1 would be a vat of

molten plutonium alloy, with tubes carrying sodium coolant passing

through the vat, and reaching a power of 20 MWth. However, early in

development it was realized that building a true molten plutonium

power reactor as a first step was premature. By 1958 LAMPRE-1 had

been changed to a more conventional design, resembling other

liquid-metal-cooled fast reactors of the time, and producing only 1

MWth of power – about enough to boil three liters of water every

second. The 20 MWth design would instead become LAMPRE-2.

LAMPRE-1's core would consist of an array of fuel elements contained in a vat and surrounded by liquid sodium coolant coming up from the bottom of the vessel, exiting from the top at 650 C and flowing to a sodium-air heat exchanger. However, instead of solid rods of uranium or plutonium, the fuel elements would be 8-inch-long, 7/16-inch-diameter hollow tubes made of tantalum, each containing 170 grams of molten plutonium alloy. The plutonium would not completely fill the tube, which would be topped off with helium gas.

There would be 199 spaces for tubes, of which about 140 would actually be used at a time. All told the reactor would contain 26 kilograms of plutonium alloy and eight cubic feet of liquid sodium. There would be no attempt to generate electricity or breed more plutonium; LAMPRE would be purely a test of the concept and materials.

This approach would allow the scientists to use some of the tubes to test different fuel alloys or container materials in preparation for the larger LAMPRE-2. Also, if one of the capsules leaked, only a relatively small amount of plutonium would escape into the coolant stream.

Figure 3: LAMPRE-1 Reactor

Core

The core would be surrounded

by an iron reflector

– a layer of material to reflect escaping neutrons back into the

core. Coarse control would be provided by a four-inch-thick hollow

aluminum shim that would push aside portions of the iron reflector;

the shim would reflect fewer neutrons back into the core, reducing

the power level. Four reflective nickel rods could be inserted into

the hollow shim to provide precise control.

A pot below the vessel would catch any leaked fuel in a non-reactive state. An iron plug was also added to the pot – in the event of a leak, hot sodium and plutonium would melt the plug, dissolving it into the mix and diluting it to an alloy with a higher melting point, solidifying it in a safe configuration.

The chamber containing the reactor would be filled with helium gas, to prevent fire if the coolant leaked, and surrounded on all sides by 3.5 feet of borated graphite, 8 inches of lead, and 5.5 feet of concrete, cooled by air to remove heat deposited by radiation.

Figure 4: LAMPRE-1 Layout

Plutonium melts at 640 C, a

number inconveniently close to the reactor's operating temperature.

Instead of pure plutonium, LAMPRE would use the eutectic

alloy of 90.5% plutonium (by atom), 9.5% iron melts at 410 C

(Pu-9.5Fe). For eventual power reactors, however, a lower – and

preferably variable – plutonium content would be better, since this

would allow more efficient heat transfer. Ternary alloys seemed to

have the greatest long term promise, in particular an alloy of

plutonium, cerium, and 12% cobalt (Pu-Ce-Co), which melts at less

than 450 C. Pu-Ce-Co would have a low melting point and allow the

plutonium content of the mix to be varied between 20% and 88% without

significant changes in the melting point. Plutonium-cerium-copper

and other ternary alloys were also under consideration, but the lab

had not finished mapping out the properties of the ternary mixes when

the fuel composition had to be decided, so they used the better

understood Pu-9.5Fe alloy.

Subcritical mockups – arrangements of materials similar to the planned core, but too small to sustain a chain reaction – were used to test the nuclear properties of the planned reactor. By 1959 components for LAMPRE were being fabricated for installation at a hot cell in Los Alamos Technical Area 35, and the scientists planned to insert the first fuel load in early 1961. The laboratory also began operating a 2 MWth gas-powered sodium-cooled steam generator in March of 1960, a 1/10th scale test model of the sodium coolant system planned for LAMPRE-2.

Tantalum

Before the reactor could go

critical, the lab first had to manufacture the fuel elements.

Extensive non-nuclear testing was done with tantalum to determine the best alloy and form of tantalum for resisting plutonium corrosion. Foils, crucibles, and capsules made of candidate materials were immersed in molten plutonium and sodium for thousands of hours, then checked for corrosion. But these static tests, while useful, were much less rigorous than the conditions to be expected in LAMPRE. In the static tests, the entire system was at approximately the same temperature, and the sodium and plutonium were not moving. In a reactor, the plutonium would attack the tantalum through mass transfer: small amounts of container material would dissolve off of hot spots in a reactor and then deposit on colder spots. It would be impossible to precisely replicate the conditions of a reactor before actually building one, but a closer approximation could be built: the TiPu, or Tipping Plutonium assembly:

Figure 5: Exterior of TiPu

Assembly

The TiPu held two candidate

capsules filled with plutonium fuel alloy. One end of each capsule

would contain a test foil and be heated electrically, while the other

was not. Every six minutes the assembly would flip 180 degrees,

simulating the movement of fuel alloy within a reactor.

Radiotracers

could also be added to the foil, allowing the scientists to map

precisely where the tantalum was going when.

Mass transfer attack, however, was secondary to attack through penetration of the plutonium through grain boundaries, particularly on the welds used to seal the capsules. As the molten tantalum solidified, contaminants such as oxygen tended to remain in the molten material, so that they concentrated in the boundaries between grains. Commercial tantalum in 1958, typically made by rolling sintered powder, had impurity levels up to 1,000 parts per million in each contaminant (other than niobium and tungsten, which are chemically similar enough to tantalum they can be ignored). It was thought that the plutonium attacked the grain boundaries by leaching these contaminants out; if higher purity could be obtained, this should mean a longer capsule life.

Figure 6: Plutonium

Penetration Through Capsule Welds

Research was already under way

in the commercial world on using arc-melting

and electron-beam-melting to produce high-purity tantalum, and

samples were acquired from several firms. Arc-cast tantalum reduced

undesirable impurities to less than 100 parts per million. Electron

beam melting of arc-melted samples eliminated all but 20 ppm, and

these were primarily confined to interstitial impurities – within

the grains – rather than intergranular.

Capsules from Metallwerk Plansee A. G. made using electron-beam melting showed particularly good resistance to intergranular penetration. These capsules were made by impact forming and ironing instead of deep drawing, which created metal grains that were thin platelets parallel to the capsule's surface, preventing the plutonium from finding a straight path through the intergranular boundaries to the exterior. Tests showed the high-purity capsules were essentially completely resistant to attack except along the welds, and had greatly improved performance there as well. However, while the high-purity capsules had superior corrosion resistance, it was not to the degree predicted by the leaching hypothesis. Apparently, the hypothesis was wrong – the plutonium was attacking the boundaries through some other mechanism. But just what that mechanism was was unknown.

As it attacked the welds, the plutonium caused the tantalum to recrystallize. Grains of tantalum within the weld would dissipate and then precipitate elsewhere in the capsule, but the exact mechanism remained unclear. Potential culprits included internal energy differences between the structure of the weld and the rest of the capsule, diffusion of copper into the weld from the chill block during welding, or contamination by thorium or other materials from the welding electrode. Whatever the cause, capsules that were annealed showed sharply improved corrosion resistance, with an hour of annealing at 1050 C doubling the average time needed for plutonium to penetrate the weld. At first glance this seemed to strengthen the internal energy difference hypothesis, as part of the effect of annealing was to sharply reduce these energy differences, but annealing at higher and higher temperatures showed continuous improvements in resistance well after essentially all energy differences should have been eliminated. All capsules annealed at 1050 C failed after 700 hours of testing, whereas none of the 1450 C annealed capsules had failed after 2800 hours. One theory was that, since chemical analysis showed that the concentration of oxygen impurities tended to vary by an order of magnitude in different places in a capsule, the annealing was homogenizing the oxygen levels, and thereby removing vulnerable spots, but this remained to be proven.

Besides annealing and improving the purity of the tantalum, a number of alloying agents were also examined, both to improve the corrosion resistance directly and as agents to draw out impurities. Researchers tested 80 different alloys using 17 different alloying elements, but found that only two showed significantly better performance.

The first was tungsten. Tungsten had been an early target of interest as it was known to be resistant to attack by plutonium, and was already used as an alloying agent in tantalum in other applications to improve its mechanical strength. The first experiments with tungsten showed improved corrosion resistance, including resistance to recrystallization, as well as an increase in the annealing temperature and smaller grains. Smaller grains means a proportionally larger intergranular region, diluting the remaining impurities over a larger area and therefore decreasing corrosion. Tungsten-alloyed tantalum was also harder to work than pure tantalum, but the advantages seemed worth it. This was an especially fortunate discovery since tungsten would inevitably be present in the container after the reactor had been operated, since tantalum is transmuted into tungsten by neutron bombardment.

Yttrium

was originally tried as a sacrificial deoxidant; that is, it was

expected the yttrium would react with oxygen during casting and

remove it from the metal. Strangely, yttrium-alloyed tantalum did

not show the expected lower levels of impurities, but had better

corrosion resistance anyway. Almost all of the yttrium left the

tantalum during the alloying process, to the point that it could no

longer be detected in the alloy, but the result nonetheless had

smaller grains and greater resistance to recrystallization.

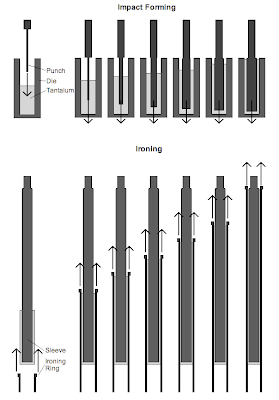

Research was still going on when the fuel capsules were ordered for the first LAMPRE-1 core. The first load would use electron-beam melted tantalum alloyed with 0.1% tungsten. The capsules would be made by cutting a 5/8-inch-diameter tantalum rod into 1.3-inch-long cylinders. Each cylinder would then be impact formed six times to produce a 2.5-inch long thimble with 0.069-inch-wide walls, then ironed six times into an 8-inch-long cylinder with 0.020 inch walls and open at one end. After machining and trimming, the capsules would be inspected radiographically to ensure they met quality standards, annealed at 1300 C – the best that could be arranged in time – a solid rod of fuel alloy inserted, and caps welded to their tops.

Figure 7: Manufacturing

Process for LAMPRE Fuel Capsules

Small amounts of carbon and

other additives would also be added to the fuel to reduce mass

transfer corrosion, in the form of plutonium carbide (in 144

capsules) or graphite discs (in 15). Additional carbon would be

added by using cast

iron instead of pure iron in forming the fuel alloy, although

this also introduced 100-500 ppm manganese and 400-800 ppm silicon as

contaminants.

Figure 8: LAMPRE Fuel

Capsule

However, soon after the fuel

decision was made, it was realized this had been a mistake. Mass

transfer was a fairly minor form of attack at the temperatures

planned for LAMPRE, and static tests showed that impurities from

using cast iron would tend to concentrate at the surface of the

alloy, and at the reactor's planned operating temperatures would

penetrate capsules annealed to less than 1,450 C. Calcium and

magnesium impurities in the cast iron also made the fuel more likely

to climb the capsule walls to reach the weld area.

But it would take time to fabricate new capsules annealed at the higher temperature and using pure iron instead of cast iron. The reactor would go critical using the capsules available, but restricted to 400 kWth power until new, stronger capsules with pure fuel could be made. Valuable data could be gathered in the meantime – in particular, a few capsules using pure iron and annealed to 1,450 C were available, and would be added to the fuel load in advance of the second loading.

Burning Metal

LASL began loading fuel into

LAMPRE on January 20th, 1961.

By this point, Kiehn had left the project. The US and the USSR had briefly observed a moratorium on nuclear tests in the late 50s, but in 1961 the Russians broke the moratorium; Kiehn led a group operating a modified KC-135 to gather data on STARFISH and other nuclear tests in the Pacific. By this point the initial nuclear design was largely finished, and the project turned over to the engineers; Kiehn later recalled that they “did not have a lot of use for an upstart physicist.” The project continued under the leadership of Byron Carmichael.

By this point, Kiehn had left the project. The US and the USSR had briefly observed a moratorium on nuclear tests in the late 50s, but in 1961 the Russians broke the moratorium; Kiehn led a group operating a modified KC-135 to gather data on STARFISH and other nuclear tests in the Pacific. By this point the initial nuclear design was largely finished, and the project turned over to the engineers; Kiehn later recalled that they “did not have a lot of use for an upstart physicist.” The project continued under the leadership of Byron Carmichael.

The LAMPRE core reached “dry” criticality – that is, without coolant – on February 17th, 1961, and “hot” criticality on March 27th.

Figure 9: LAMPRE Core Prior

to Operation

The core began losing

reactivity almost immediately. The problem was eventually traced to

the buildup of neutron-absorbing fission product gases, which were

bubbling on the surface of the fuel alloy. Capsules removed from

the core revealed that the carbon additives were forming solids,

which the team dubbed “crud”, on the surface of the fuel alloy,

keeping the bubbles from escaping.

Figure 10: Radiograph of

LAMPRE Fuel Capsule Showing “Crud”

Excessive radiation also

leaked into the control room through inadequately plugged conduits,

and through the top shield; both had to be beefed up. A sodium

circulation pump failed early in operation; fortunately,

temperature-induced circulation kept enough sodium moving to avoid

having to shut the reactor down.

Nitrogen was also detected in

the helium cover gas, suggesting a possible leak. If air was

entering the system, the oxygen would be absorbed by chemical traps

in the sodium lines, explaining why it was not detected. But

eventually the chemicals in the traps would be exhausted, and buildup

of oxygen in the sodium would cause it to attack the tantalum fuel

capsules. However, tests failed to locate any leaks, and eventually

it was determined that the nitrogen was actually diffusing through

the metal of the coolant lines. Without any means of preventing the

nitrogen from entering, the team settled for periodically purging and

replacing the helium cover gas.

Then, shortly before the reactor run was completed, the reactor control shim started responding sluggishly. Since the shim was the scram control, to be used for rapid shutdown of the reactor in an emergency, this was a major problem. The shim response speed seemed to vary depending on reactor temperature, suggesting that thermal expansion was causing friction somewhere in the mechanism. However, the exact source was never conclusively determined since the components were too radioactive by this point for manual inspection, and the shim was not fitted with sensors to determine its temperature directly.

The scram function was transferred to the four fine control rods, and a baffle was added to the shield cooling system to increase the amount of air used to cool the shim. This task was made more difficult because the only access was by clambering through an air duct, and radiation in this area was intense enough that personnel could only be sent in for brief periods at a time.

On January 22nd, 1962, the reactor was shut down and the fuel frozen for unloading. The second core load removed the carbon additives, used pure iron instead of cast iron, and used capsules annealed to 1,450 C. The new capsules were made of a mix of materials, some made of tantalum alloyed with 0.1% tungsten, some pure tantalum, and the rest tantalum alloyed with 0.75% tungsten and 0.2% yttrium. The reactor went critical again on April 20th, successfully achieving a full megawatt of power on July 15th.

The first capsule failed on September 15th. 90 grams of molten Pu-9.5Fe fuel leaked into the sodium coolant. After the capsule was removed, metallurgical analysis showed the capsule had failed due to intergranular penetration and had probably been leaking fuel for some time, and was only discovered when the leak rate increased enough that the loss of reactivity was detected. After this, reactor power was limited to 500 kWth. Two more capsules failed on May 15th 1963, releasing fuel under 375 psi pressure from fission gases into the coolant, and operations with the second core were terminated in July.

By this point, several fuel capsules had bonded to their handles. Metallographic examination of the capsules showed severe integranular penetration in the welds in 80% of the capsules, although no penetration was detected outside of the weld regions.

Overall, even with the various bugs, the first two LAMPRE runs was judged a success. The reactor responded as predicted, demonstrating the promised negative temperature coefficient of reactivity. Some tendency for power to fluctuate was observed in the second core loading, with sodium outlet temperatures varying up to 30 C, but not to a degree that could damage the reactor. And valuable data had been gathered on materials performance; in particular, the second core load had included several test capsules containing Pu-Ce-Co fuel alloy, which had performed excellently.

Plans were now well under way for the third core loading, to test Pu-Ce-Co fuel alloys, although many of the capsules would still have to be Pu-9.5Fe for the core to attain criticality. The capsules would also be annealed to 1,600 C if an appropriate facility could be located in time. Assuming all went well, LAMPRE-1 would go critical a third time by March 1964.

References

History of

Reactor Development:

Bunker,

Merle E. “Early Reactors: From Fermi's Water Boiler to Novel

Power Prototypes.” Los

Alamos Science,

Winter/Spring 1983, pp. 124-131. Link

(pdf).

Hewlett,

Richard G., and Holl, Jack M. A

History of the United States Atomic Energy Commission, Vol. 3:

1952-1960 – Atoms for Peace and War.

Link

(pdf).

Till,

Charles, and Yoon, Il Chang. Plentiful Energy: The Story

of the Integral Fast Reactor.

CreateSpace, 2011.

Weinberg,

Alvin. The First Nuclear Era: The Life and Times of a

Technological Fixer. AIP

Press, 1994.

LAMPRE:

Dr. Kiehn, R. M.

(LASL). Personal communication.

Lane,

James A. Fluid

Fuel Reactors.

US Atomic Energy Commission, 1958. Link.

Los

Alamos Scientific Laboratory. LAMPRE

I Final Design Status Report.

Los Alamos Scientific Laboratory, 1962. LA-2833. Link

(pdf).

Petersen,

R. E. “Operation of the Plutonium-Fueled Fast Reactor LAMPRE.”

Fast Reactors: Operating, Under Construction, Planned for

Construction. National Topical

Meeting, San Francisco, CA, April 10-12, 1967. Vol. 2 No. 2, 1967.

Quarterly Status

Reports on LAMPRE Program. Link.

Swickard,

E. O., et al. Los

Alamos Molten Plutonium Reactor Experiment (LAMPRE) Hazard Report.

Los Alamos Scientific Laboratory, 1959. LA-2327. Link

(pdf).

Tantalum

Dr. Anderson, T.

(University of Sheffield, Dept. of Chemistry). Personal

communication.

Bidwell, R. M.

“Molten Plutonium Fuel Development (Metallurgy).” Proceedings

of the Fast Reactor Information Meeting, 1957. Atomic Energy

Commission, 1959.

Bidwell, R. M.,

Ferguson, William E., et al. “The Development of High Purity

Tantalum and Alloys for Liquid Plutonium Containment in LAMPRE I.”

Nuclear Science and

Engineering, Vol.

14, 1962, pp. 109 – 122. Link

(pdf).

Hall, D. B.

“Plutonium as a Fuel for the Los Alamos Molten Plutonium Reactor

Experiment.” Proceedings of the Conference on Plutonium as a

Reactor Fuel, December 1962.

Thamer, B. J.

“Corrosion Tests with Molten Plutonium Fuels.” Proceedings

of the Conference on Corrosion of Reactor Materials.

International Atomic Energy Agency, 1962.

Pictures

Figure 1: From

Plentiful Energy. US Government.

Figure 2: From

“Early Reactors.” US Government.

Figure 3: From

“Quarterly Status Report on LAMPRE Program for Period Ending May

20, 1960.” US Government.

Figure 4: From

Adams, Steven R., Theory, Design, and Operation of Liquid Metal

Fast Breeder Reactors, Including Operational Health Physics.

EGG-2415. US Government.

Figure 5: From

Bidwell, R. M. “Molten Plutonium Fuel Development (Metallurgy).”

Fast Reactor Information Meeting, 1957. Paper IV-C-1. US

Government.

Figure 6: From

“Corrosion Tests of Molten Plutonium Fuels.” US Government.

Figure 7: Author.

Figure 8: From

“Operation of the LAMPRE”. US Government.

Figure 9: From

“Operation of the LAMPRE”. US Government.

Figure 10: From

“Quarterly Status Report, Aug. 1961”. US Government.

.png)

.png)

No comments:

Post a Comment